Audi’s A6 Sportback E-tron has a drag coefficient of 0.21, a low figure for a sizeable car. How do they do it?

Aeros play a major role in the amount of energy used to keep a car rolling at a constant speed. Drag increases dramatically with speed; with each doubling of velocity, the drag quadruples. That clearly has a major effect on fuel or electricity consumption.

Reducing the drag involves more than merely making a car slipperier. It’s essentially a compromise between aesthetics and efficiency.

Audi was one of the pioneers of improving aerodynamics in production cars. In 1983, the Audi 100 had the lowest drag coefficient of any production car (0.30).

Skip ahead forty odd years and it’s a similar result with the A6 Sportback E-tron; its Cd of 0.21 is the lowest of any Audi yet.

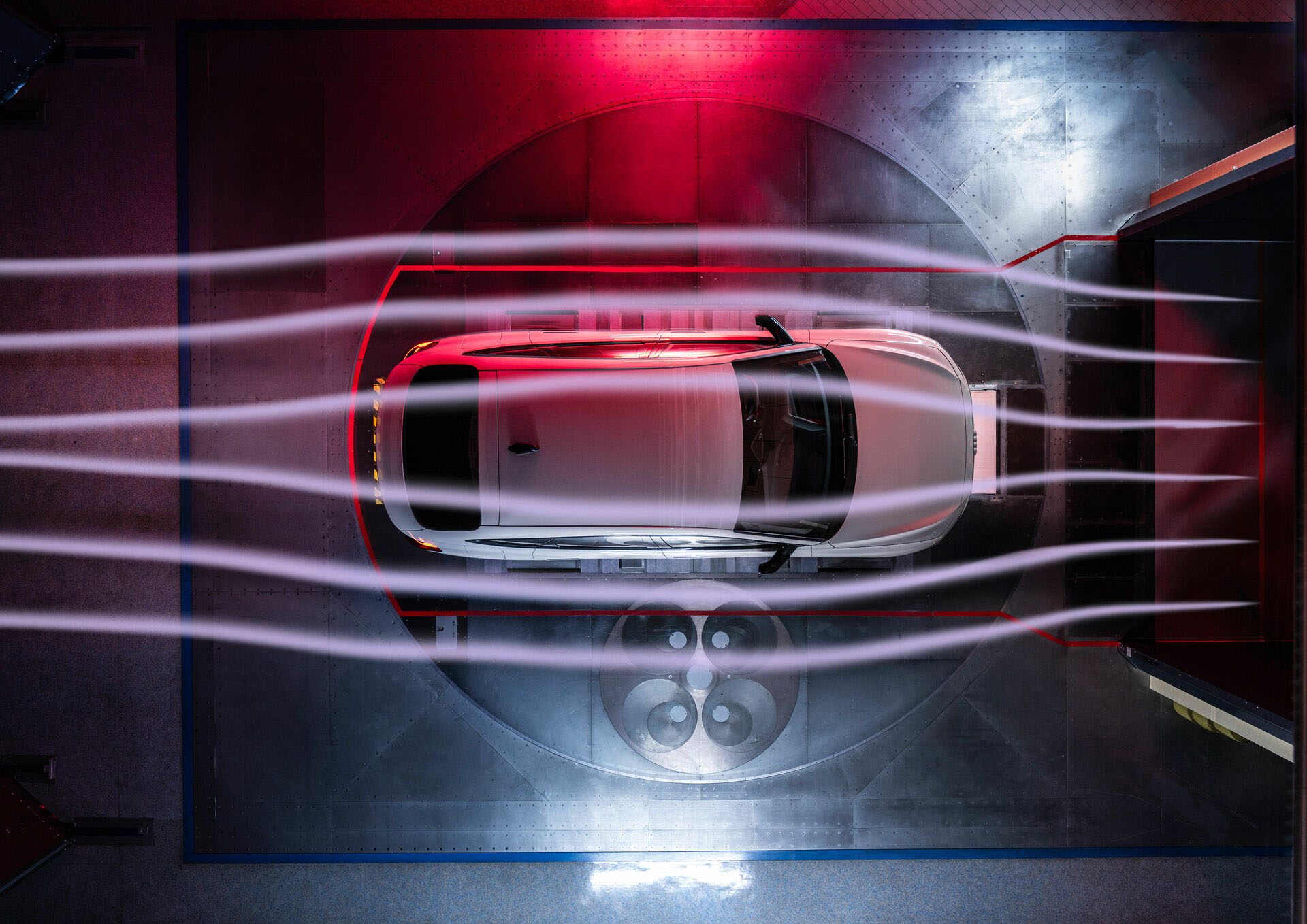

The aerodynamics team ran almost 1300 simulations after initial design work, and then built physical models for wind tunnel testing. That’s where effects of small details could be assessed.

In the original design the outside edge of the intake for the air curtain (deflects air around the front) protruded overly. A small modification improved subsequent airflow.

Fine tuning the cool air intake below the front grille and some surface edges encouraged the airflow to separate. That reduces low pressure in key areas.

Detail work on undertray areas gained a further advantage – the rear axle is mostly covered – as did tweaking the wheel designs. The rims must be flat so the air can flow smoothly across the face. A 21-inch wheel with aero blades made the cut.

The basic shape of the car, especially at the rear, and the underfloor design affect not only the car’s Cd value but also lift generated. Tweaking the underfloor details achieve the ideal blend between Cd and lift, to achieve the optimal aerodynamic shape.