Honda’s 0 Series Saloon concept, shown at CES in January, previewed the first of seven planned models in the line-up. They will all use a new purpose-built EV platform. Honda plans to reveal a model that will be “the embodiment” of the technologies at CES next year.

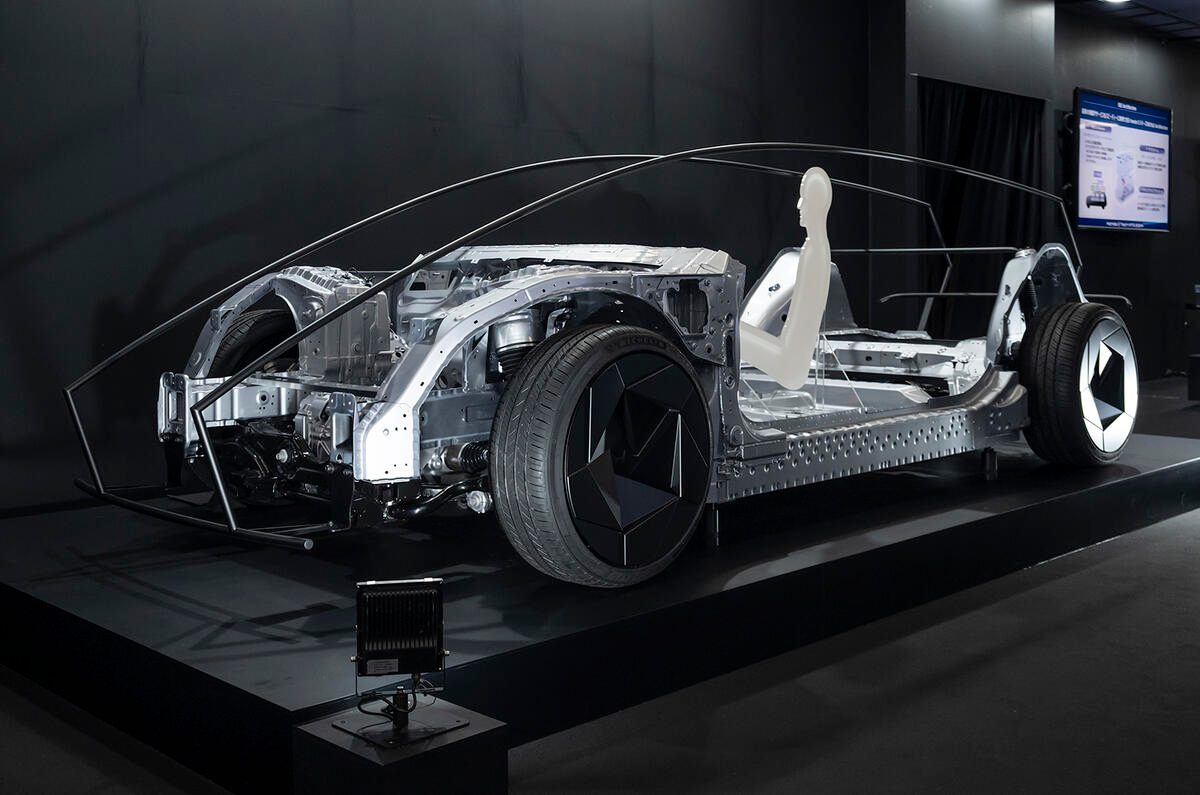

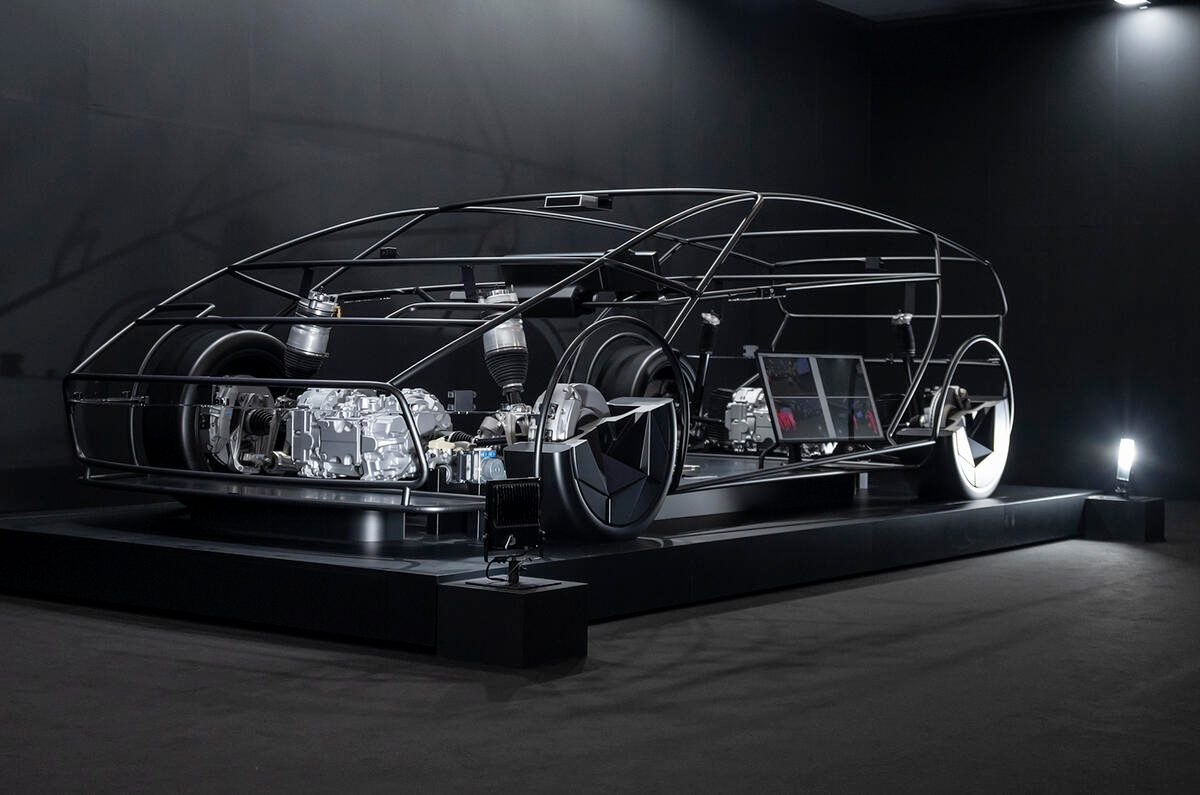

The 0 Series Saloon will come in single- and dual-motor powertrains. Honda has developed new compact e-axles that it says can be mounted lower in the car. The e-axle motors are less bulky by repositioning the inverter. That permits a smaller frontal area to improve aerodynamic efficiency.

Base models will come with a 180kW motor on the rear axle and rear-wheel drive. The range topper will feature the same motor on the front as the rear axle, giving a system output of 360kW.

There will also be a 4WD version that mates the 180kW rear motor with a smaller 50kW unit on the front axle. That smaller e-axle will be shared with Honda’s next-generation hybrid models.

The battery pack will fit under the floor, as in other EVs, but it is 8mm thinner than EV batteries from rival firms. The upshot is that the saloon is less than 1400mm tall for better aero. It will also offer more interior space than current EVs.

Megacasting will be used to produce the battery pack case in three parts. Previously 60 pieces were needed. Down the line, Honda will use megacasting to produce the front and rear assemblies of the car as single pieces. That will happen when a new EV assembly plant in Canada opens in 2028.

Medium and large 0 Series models will feature NMC battery chemistry. With capacity up to 90kWh, range should exceed 500km. The biggest models will feature a pack offering around 100kWh.

Honda will use a number of new production techniques designed to increase platform rigidity while also reducing weight. More use will be made of a system called ‘3D friction stir welding’. This procedure can join metals without melting them. ‘Constant DC chopping’ (CDC) spot welding controls the heat used to weld joints better. The use of both manufacturing techniques is claimed to result in greater strength and less deformation.

Another innovation is a body structure that disperses the impact of a collision to the side of the vehicle, reducing the space at the front and rear needed for battery protection.

Honda hopes the O Series Saloon will be around 100kg lighter than rival EVs, aiding efficiency and agility. Steer by wire is on the cards so the yoke of the concept car may make it to production.

Other special features include active aerodynamics that can channel air underneath through sculpted bodywork, and 3D gyro sensors to stabilise the car automatically.

Evidently the lightweight aluminium frame flexes during spirited cornering, transferring load to the outside of the wheels to improve cornering balance.

Over-the-air software updates will be possible, and expect level three autonomy in certain situations, thanks to a range of camera, radar and lidar sensors. This means the car drives itself but the driver must be ready to intervene if necessary.

Following the 0 Series Saloon launch in 2026, a slew of different sized electric SUVs will debut in the following few years. Production of the 0 Series models will kick off in Ohio, with ICE and EV models made on the same line. This makes catering for demand easier.

A new EV production and battery plant is due for completion in Ontario, Canada by 2028.