Mercedes-Benz is developing what it calls “in-drive brakes” for EVs.

All but a few cars use disc brakes. They consist of a rotor attached to a hub acted on by a caliper/pads that are fixed to the control arm of each wheel. Hydraulics force the brake pads against the rotor. That sllows the rotation of the hub, and thus the wheel and car.

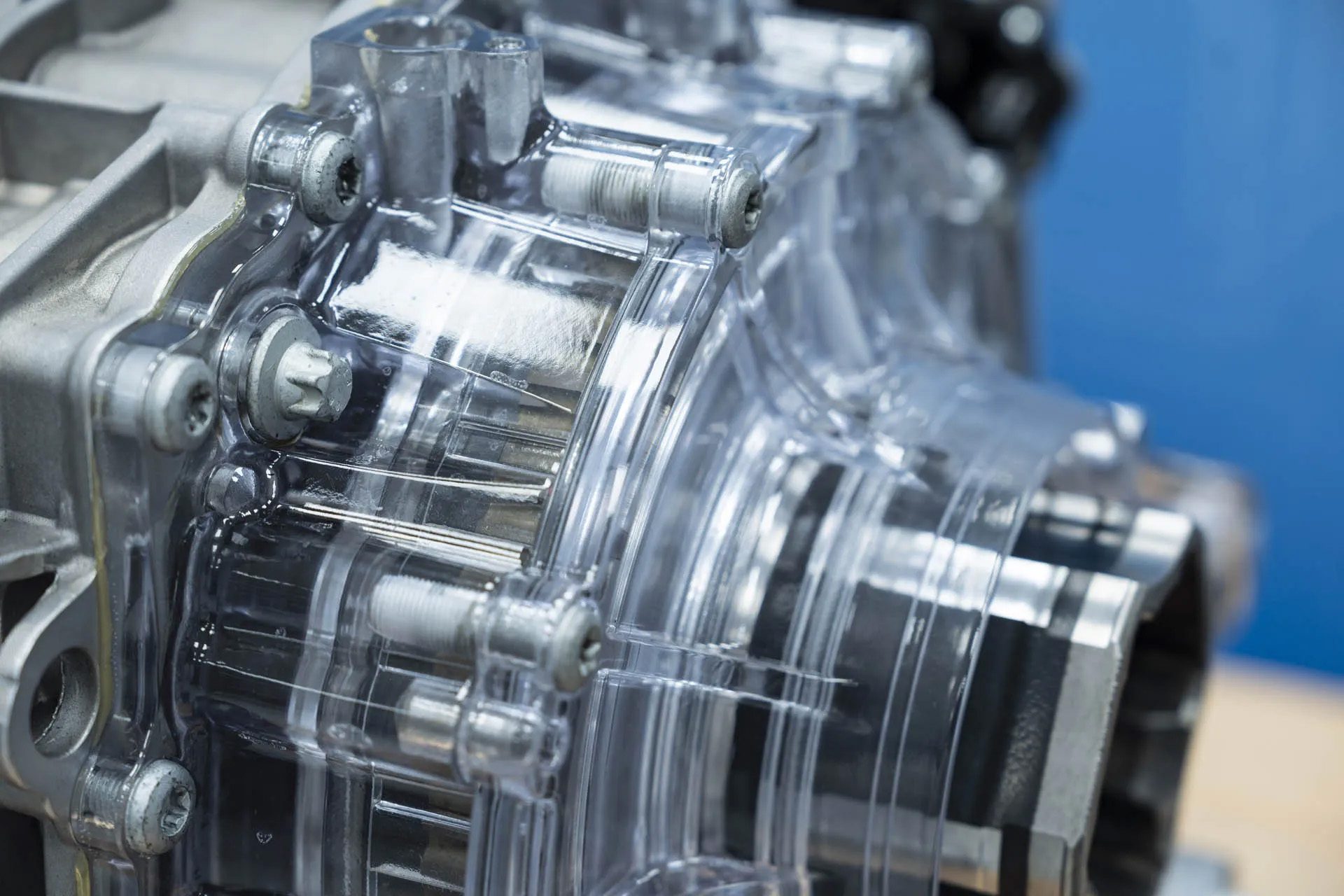

Now Engineers are integrating the brakes right into the drivetrain, within the EV motor housing. Mercedes says the in-drive brakes could also be mounted to the front axle even if there’s no motor.

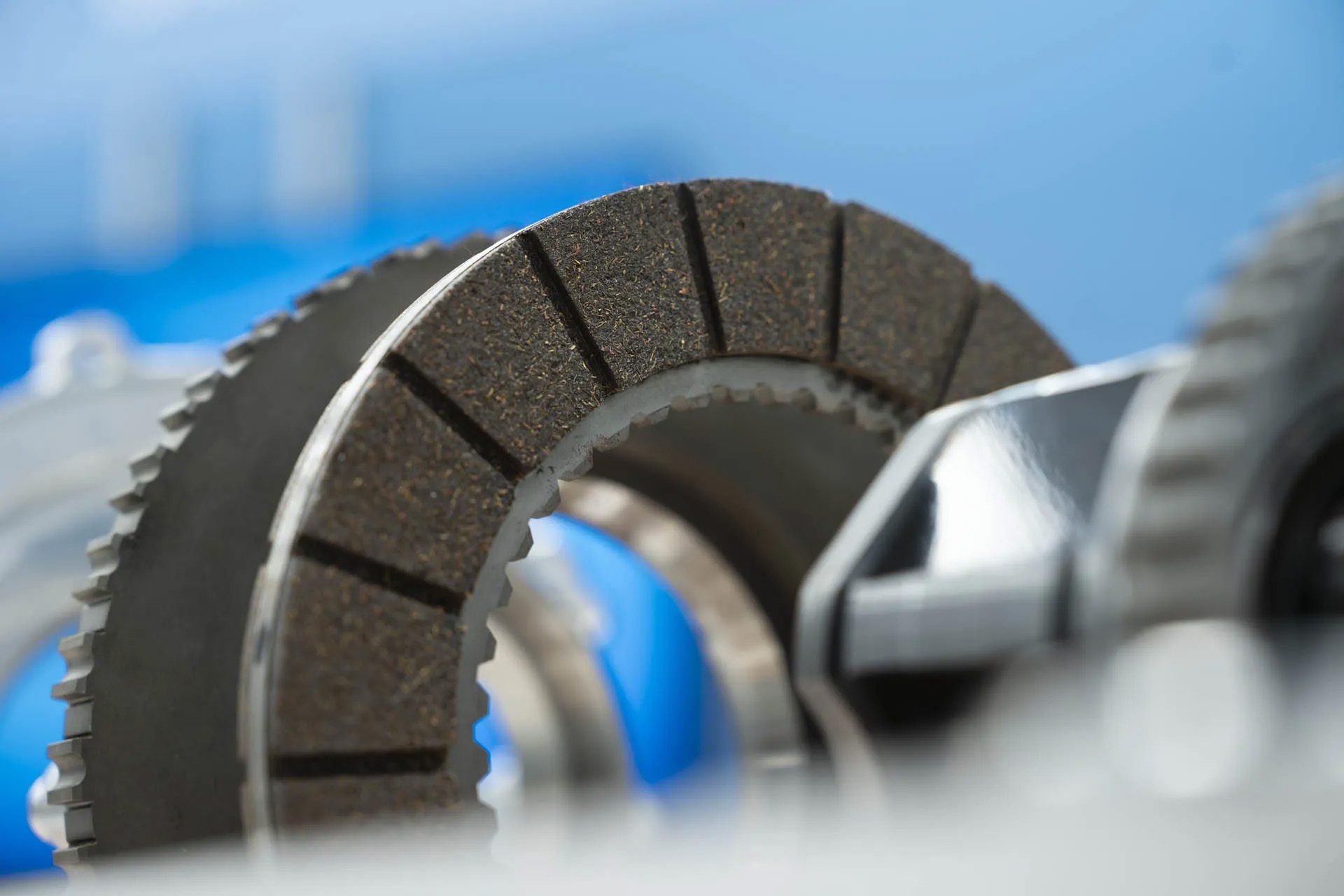

The system takes up very little space, is subject to low wear and, being enclosed, makes little noise and no dust emissions.

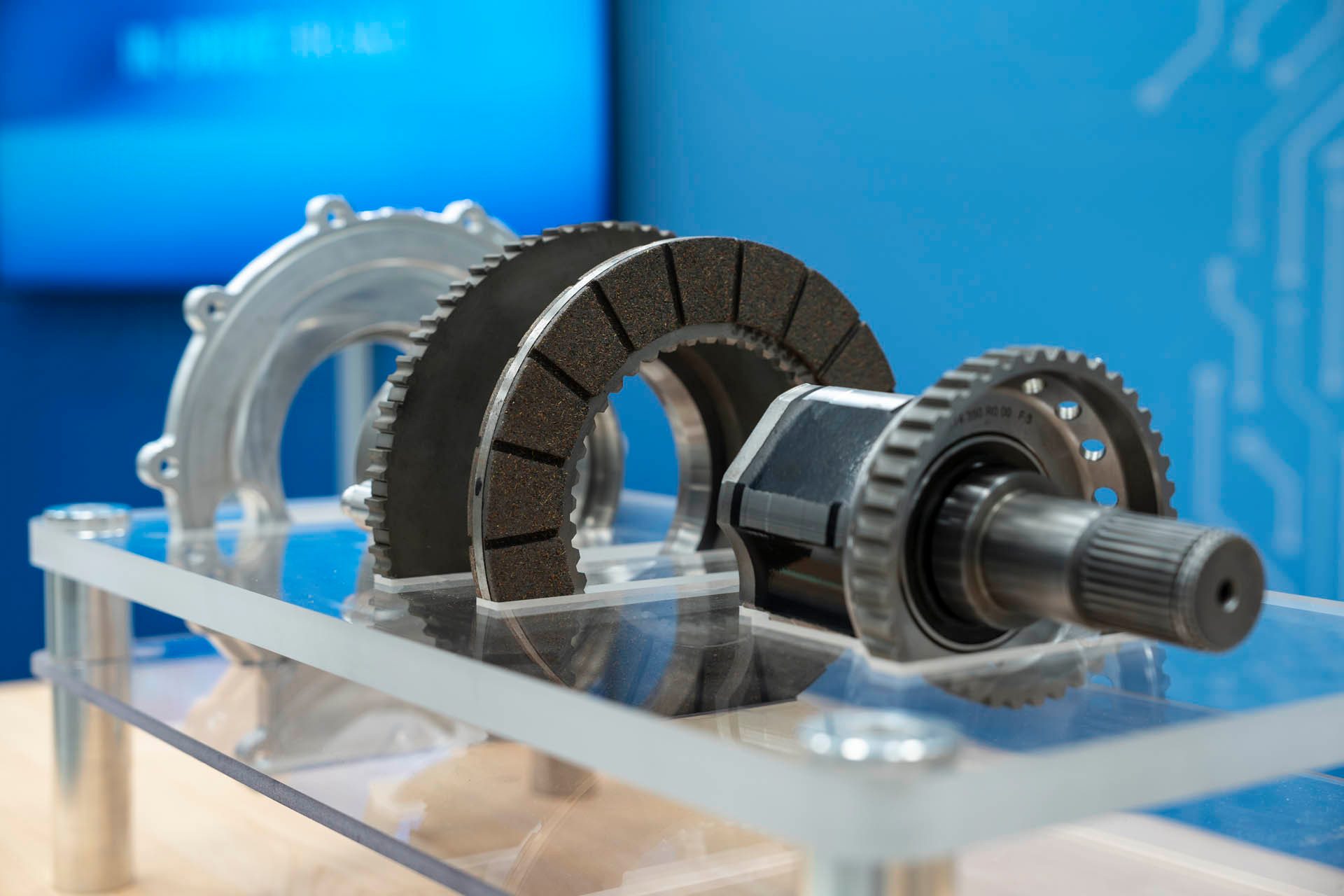

The brake discs are located on either side of the electric motor and are liquid cooled. Wear is likely to be low too, given Mercedes suggests mechanical braking in EVs is only required about two per cent of the time.

There are no calipers, and instead a circular brake pad connects directly to the output shaft of the electric motor. This presses against a stationary water-cooled ring, all within an enclosed system. Where currently pads only slow a small part of any disc brake, the in-drive system uses the entire ring. Therefore, less brake force is required in operation.

Mercedes states it requires no servicing and essentially lasts for the life of the vehicle, clearly an enormous service saving. The system is expected to last for 15 years or 300,000km.

Any brake dust produced collects in a small compartment that doesn’t need emptying. This then is a significant environmental advantage, especially with Euro 7 emissions standards taking effect from 2026.

EV motors act as a brake when the accelerator is released, the motor then regenerating kinetic energy into electricity that goes back into the battery pack, slowing the vehicle in the process. But it cannot bring the vehicle to a halt; an actual brake system is still needed.

While it is not yet ready for production, Mercedes says that brake fade will be a non-issue because the system is liquid-cooled. Moreover, all of the mechanicals involved in slowing the vehicle are no longer in or near the wheels, reducing unsprung weight. So gyroscopic effect from the wheels reduces, improving handling and ride. Wheels can also be designed for improved aero, eg, fully closed rims, given there are no longer rotors or calipers or the need for cooling these.

Aesthetically, there’s no more filthy brake dust on your shiny alloys. So wheel cleaning won’t be such a chore.

Mercedes is evidently still be testing this system and has no time line for production. However, the company is already calling it “the brake of the future”.