High-strength graphene roads could banish potholes

Words NZ Autocar | Images Wikipedia, Interesting Engineering

Graphene is one of the strongest materials known to man. In the future it may play a role in the seemingly never-ending battle against potholes.

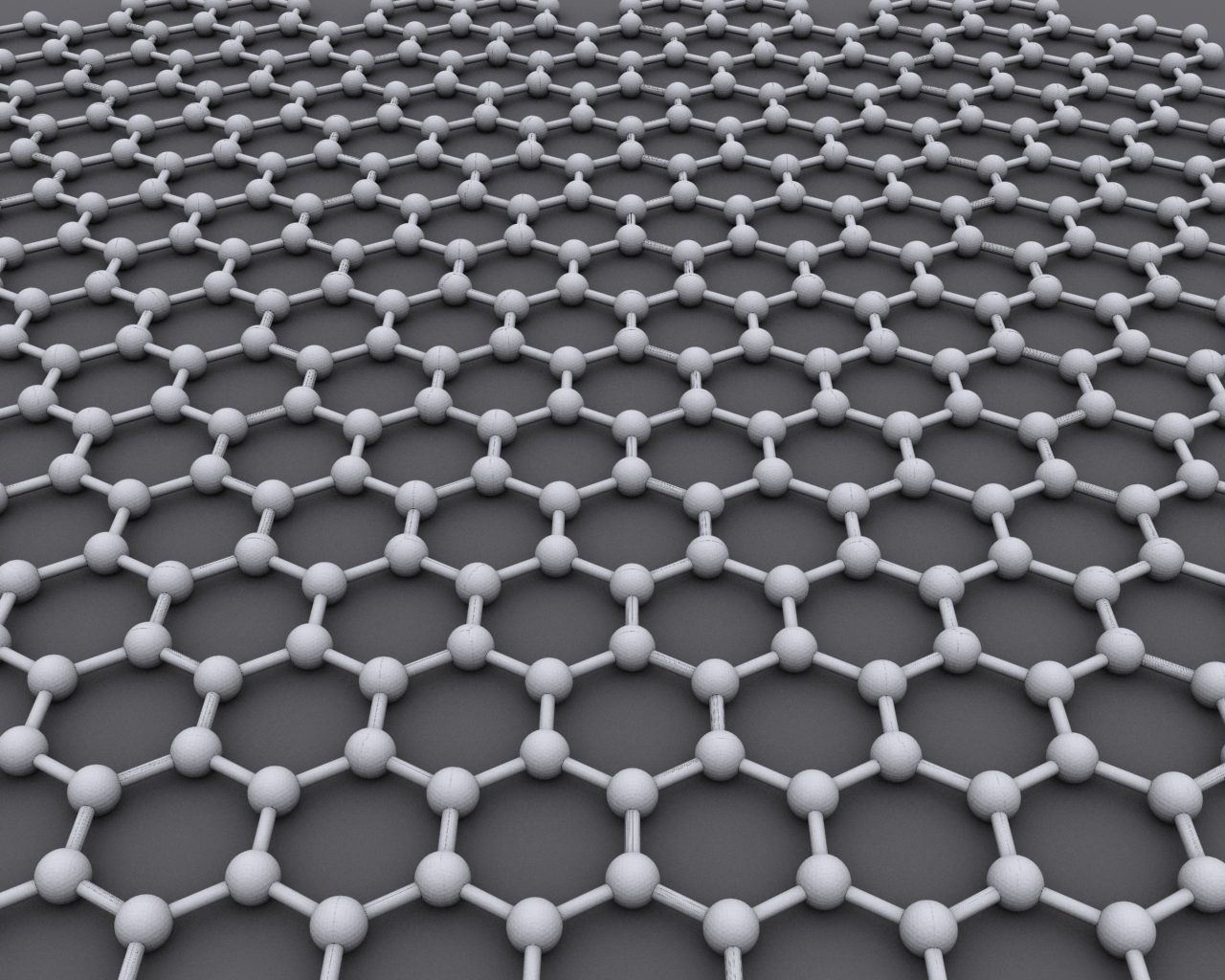

Graphene is essentially a single-layer honeycomb of carbon atoms, and is 200 times stronger than steel. It is also conductive which may yet play a role in roads as EV charging hubs. And it has a lower carbon footprint than asphalt.

Despite its strength, it can stretch to over twice its own length. Because of that strength and elasticity, roading engineers have incorporated graphene into a road surfacing material. The product is a collaboration between graphene specialist Universal Matter and UK road construction firm Tarmac. The pair recently rolled out the first stretch of UK public road in a trial of graphene-enhanced asphalt.

The goal is clearly a longer lifespan for roads that will be more resistant to damage caused by heavy traffic and weather. Evidently adding graphene reduces the development of ruts and cracks over time, limiting the appearance of potholes. These cost the UK around £150m annually to repair, while vehicle damage caused by potholes is estimated at £0.5b per annum.

Andy Gent, commercial director for the graphene firm, commented “It’s great to see it taken from the lab stage to full road application. This product has great potential, and we are delighted that Tarmac agreed to participate.”

The mix was laid on a new entrance road that is on the outskirts of Middlesborough.

A spokesperson for the local council’s highways department said “We take pride in being at the forefront of sustainable, cutting-edge technology that not only improves our roads but also benefits motorists and the environment.”

Graphene-enhanced asphalt is also on trial in car parks in North America. However, this is the first use of the material on a public road.