Hyundai and Kia reveal clever Uni Wheel EV drive system

Words: Harrison Wade | Photos: Hyundai

Korean carmakers Hyundai and Kia have teamed up to create a radical new system for their future electric vehicles that moves the main drive components to the wheel hub.

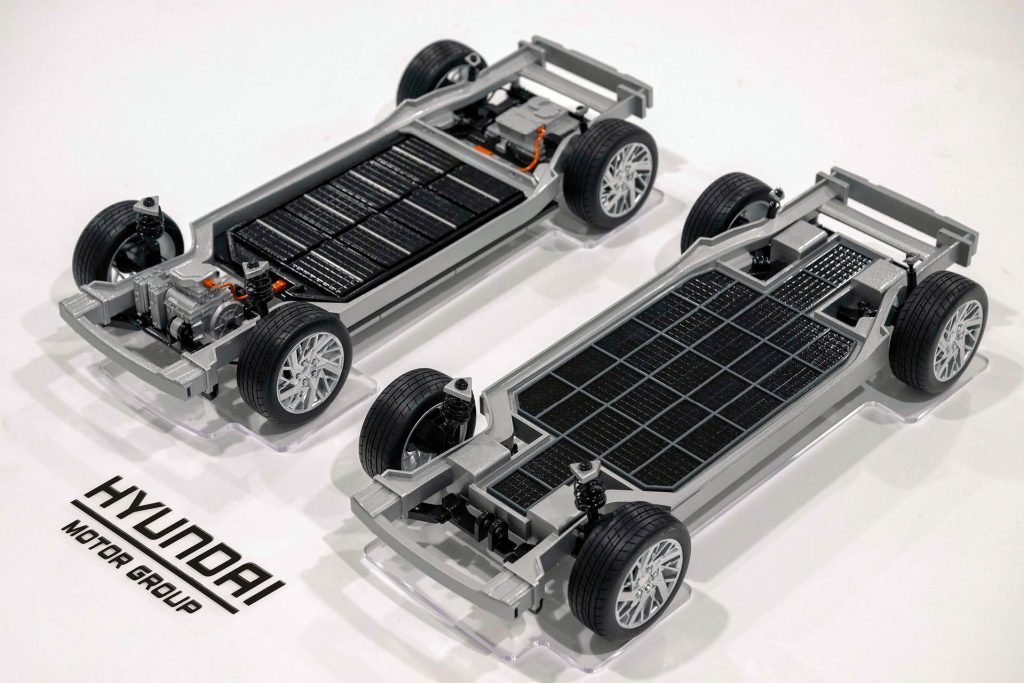

It’s called the Universal Wheel Drive System, or simply Uni Wheel, and it has been designed to optimise cabin space and allow for larger batteries to be fitted.

Conventional electric motors have built-in reduction gears to transfer power to each wheel and their design can often take up a fair amount of space.

Hyundai and Kia’s new system moves the aforementioned reduction gears to the vacant space within each wheel hub, allowing the placement of a compact e-motor close to each wheel. This also reduces the length of the drive shafts and ultimately takes up less space.

Uni Wheel is made up of a special planetary gear configuration which consists of a sun gear in the centre with four pinion gears on each side, and a ring gear surrounding the arrangement.

The e-motor sends power to the sun gear which then turns the pinion gears that rotate the ring gear, driving the wheel.

While Uni Wheel was designed for applications like purpose-built vehicles (PBVs) and passenger cars, it can also be used in wheelchairs, bicycles, and even delivery robots.

Hyundai and Kia are still developing the new drive system and have already applied for and registered eight patents in South Korea as well as the United States and Europe.