Nissin and Showa have developed a fork and brake caliper system that’s built as one piece, offering extra strength.

All existing motorbikes have either axial- or radial-mount brake calipers. Both attach to the fork. Neither has the caliper directly fitted to the fork, at least until now.

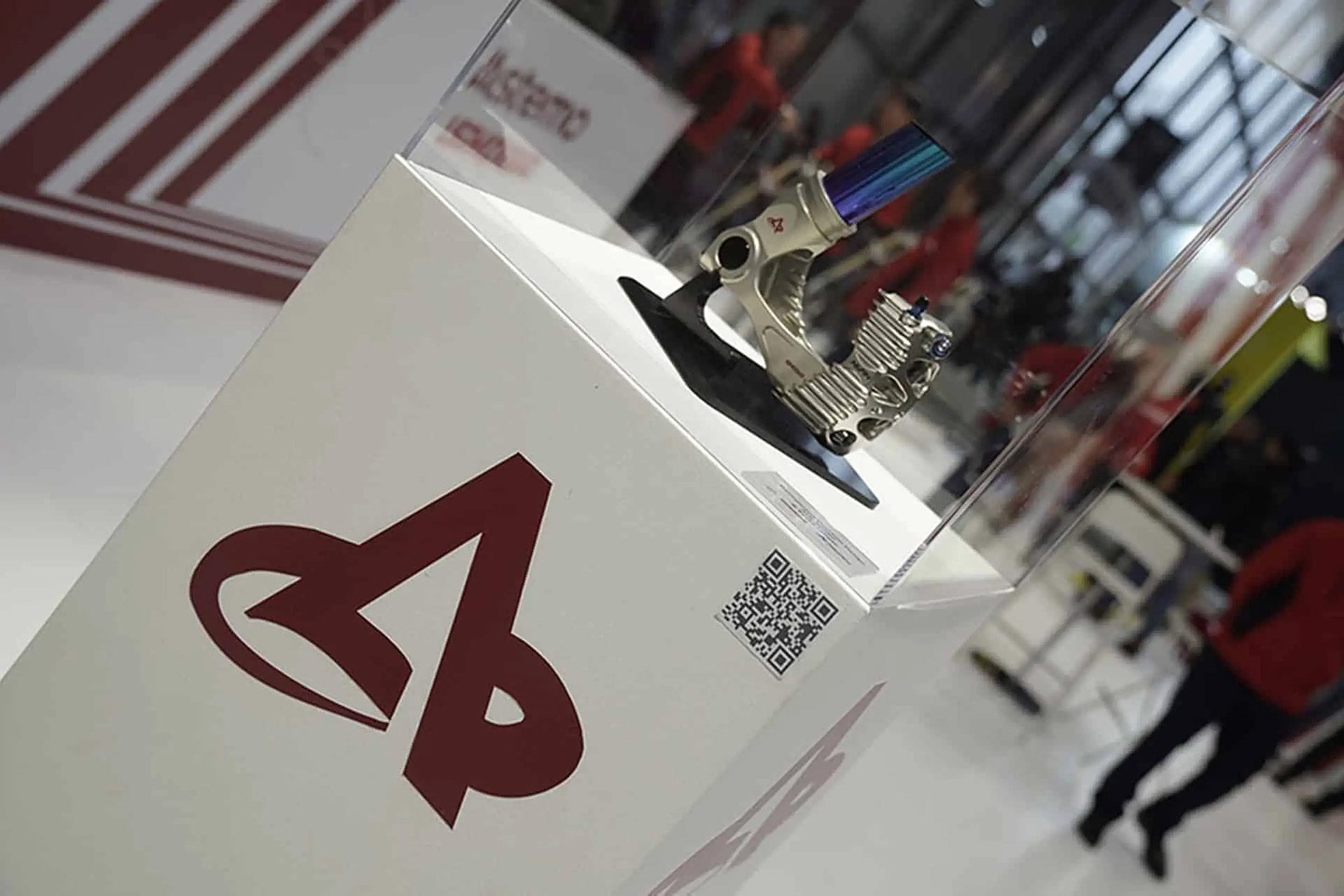

In this new design, both the caliper and the bottom of the fork leg are machined from a single aluminium billet. This helps to increase the contact area between the caliper and the fork axle support by almost one-third.

What are the advantages, you may ask? Firstly, it increases rigidity. Under extreme braking, traditional set-ups frequently flex, reducing performance. Showa and Nissin assert that this new approach offers better stability in use, thanks to the increased surface area where these parts meet.

There’s also improved heat dissipation, important for consistent braking performance on track. The new design offers a more efficient flow of heat away from the braking components, reducing caliper temperature by up to five per cent.

And there’s less weight in this set-up. Compared with traditional radial-mounted systems, Showa and Nissin’s integrated design promises a weight savings of at least 200g.

The primary downside is that it is more difficult to service both the forks and brakes. And price may also be an issue.

Ultimately, users will decide if this has real world advantages. Expect it to end up on race bikes first for testing at extremes, before road bikes.