It would appear that Stellantis, owners of 13 brands, has turned a corner with lithium-sulphur technology. Or its Zeta Energy partner has.

This tech has the potential to halve the cost per kWh, improve rapid-charging speed by 50 per cent and weigh significantly less than existing technology. Stellantis reckons the new battery packs will power its vehicles by the turn of the decade.

The lithium-sulphur battery tech is pioneered by Texas company Zeta Energy. It has been working on lithium-sulphur batteries for over a decade and is cooperating with Stellantis on its development.

The advantage of lithium-sulphur battery tech is high energy density (450wh/kg). That’s three to five times greater than that for LFP and NMC lithium-ion batteries. Lithium-sulphur tech also promises faster charging rates, and requires no nickel, manganese, cobalt or graphite. Zeta Energy says their batteries are good for at least 2000 cycles.

The main differences lie in cathode and anode chemistry. All lithium-ion EV batteries have graphite-based anodes, with cathodes consisting of the materials that give each different type its name.

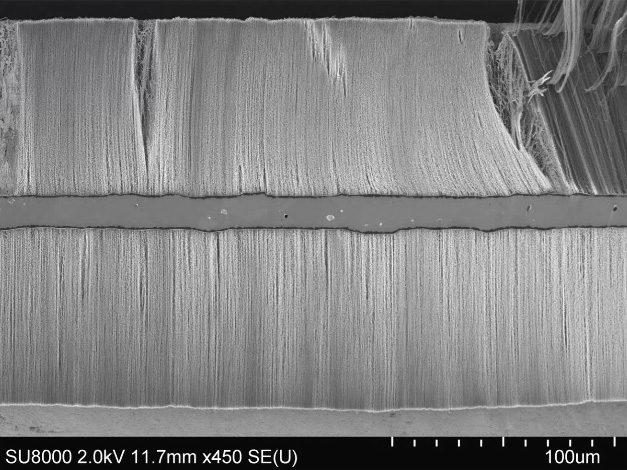

Lithium-sulphur batteries promise fast charging as well, but there have been problems in development. The main concern is anodes that grow dendrites. These can penetrate the separator membrane between the two electrodes, causing a battery short circuit.

A solution is platinum-doped gold and graphene sheets for preventing dendrite formation. However, these are expensive.

The Zeta Energy cathode is based on sulphurised carbon materials. The company says it is stable and gives better performance than existing metal-based cathodes.

The Zeta Energy lithium-sulphur battery anodes comprise vertical carbon nanotubes that don’t produce dendrites.

This new type of battery has the potential to make EVs substantially cheaper.

However, Stellantis is not forsaking lithium ion tech; it has just announced a JV with CATL to build an LFP factory in Spain.